Essential Components for a Fully Automated Hydroponic Setup

Establishing a fully automated hydroponic system demands meticulous planning (1) and the appropriate combination of crucial components. A meticulously designed automated system can save time; reduce labor and optimize plant growth—this is vital for maintaining consistent growing conditions. However, one must consider potential challenges, although the benefits are substantial, because proper execution can lead to impressive yields.

Core System Components

A dependable reservoir (1) functions as the cornerstone of your automated hydroponic system, holding nutrient-laden water for your plants. It’s essential to select a food-grade container that is suitable for the size of your setup; furthermore, ensure that it is lightproof (because this will help prevent algae proliferation). Connect this reservoir to a high-quality water pump, which will effectively circulate the solution throughout your growing system. However, do not overlook the importance of regular maintenance, although it may seem tedious, because it directly impacts the health of your plants.

The nutrient delivery system consists of:

• Programmable dosing pumps

• EC (electrical conductivity) sensors

• pH sensors

• Digital controllers

• Distribution manifolds

Environmental Control Systems

Temperature management (indeed) plays a vital role in the health of your plants. Installing circulation fans is essential to maintain uniform air distribution and to prevent hot spots. A programmable thermostat (which is connected) to your ventilation system assists in maintaining optimal growing conditions throughout the day. However, your environmental control setup should include various elements to ensure success.

• Thermostats

• Humidity sensors

• CO2 monitors

• Smart ventilation fans

• Air conditioning or heating units

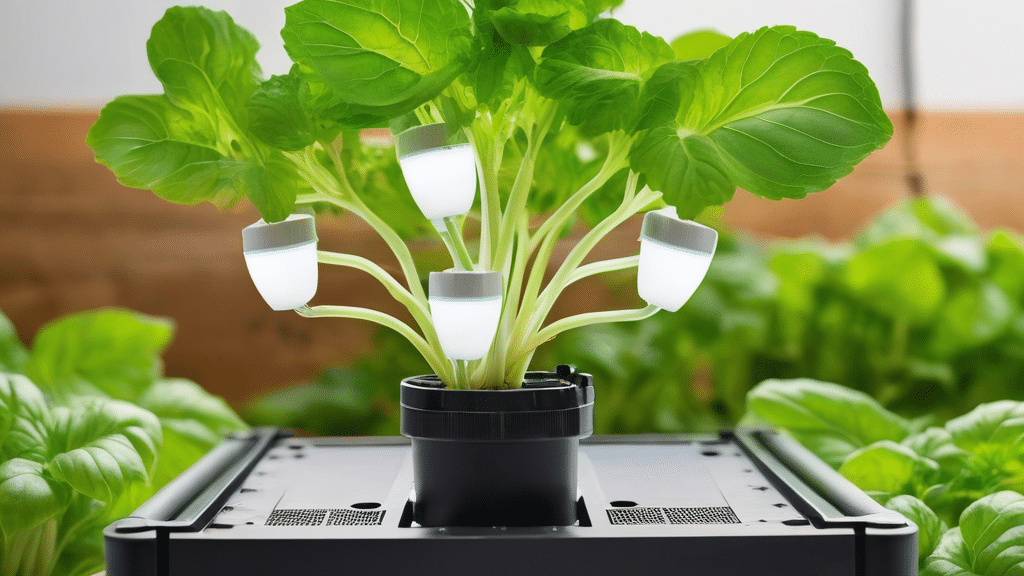

Lighting Automation

Modern LED grow lights (which feature built-in timers and intensity controls) constitute the backbone of a lighting system. These lights can be connected to environmental controllers that adjust light intensity according to plant growth stages and ambient conditions. Smart power strips allow for remote control and scheduling of your lighting system (through mobile apps). However, the integration of these technologies can be complex, but it offers significant advantages. Although some users may find the initial setup challenging, this complexity is often outweighed by the benefits of precision in lighting management. Because the right light at the right time can greatly enhance plant growth, investing in such systems is often worthwhile.

Monitoring and Control Hub

A central control system (which integrates all components) operates via a digital interface. This hub processes data from various sensors and adjusts system parameters accordingly. Modern controllers often feature wireless connectivity for remote monitoring and control—this is facilitated through smartphone applications. However, one must consider the challenges that arise with such technology; although it offers convenience, it can also present security risks. Because of these factors, careful implementation is crucial.

Essential monitoring features include:

• Real-time data logging

• Alert systems for parameter deviations

• Historical data analysis

• Remote access capabilities

• Automated adjustment protocols

Backup and Safety Systems

Implementing reliable backup systems is essential to safeguard your investment. For critical components, it is advisable to install uninterruptible power supplies (UPS); this ensures a continuous power supply. Furthermore, backup water pumps should activate automatically if the primary pump fails, however, you might also consider adding water level sensors and leak detectors to prevent system failures. Although these additions might require initial investment, they ultimately provide peace of mind and efficiency.

Maintenance Components

Regular system maintenance (1) is essential for long-term success; however, it often requires careful planning. Installing auto-flush valves can be beneficial, as they periodically clean the lines and help prevent salt buildup. Automated cleaning systems, because they are efficient, can significantly assist in maintaining the proper functioning of pumps and filters. Furthermore, including water filtration systems with automated backwashing capabilities is important—this ensures consistent water quality. Although some may overlook these details, neglecting them can lead to larger issues down the line.

Key maintenance features:

• Self-cleaning filters

• Automated system flush cycles

• UV sterilization systems

• Sediment removal systems

Chemical injection systems designed for cleaning play a crucial role in modern agriculture. Integrating these components (such as pumps and nutrient injectors) creates a robust automated hydroponic system that necessitates minimal daily intervention. The initial investment in quality automation equipment is worthwhile; it pays off through reduced labor costs, consistent crop quality and enhanced resource efficiency. Regular system checks—along with occasional calibration of sensors—ensure that your automated system continues to perform optimally. This, in turn, provides reliable crop production throughout the growing season.

However, it is important to remember to choose components that can communicate effectively with each other and your central control system. This compatibility not only ensures seamless operation but also allows for future upgrades as your hydroponic operation expands. Although proper planning and implementation are essential, your automated hydroponic system will ultimately offer years of dependable operation while maximizing crop yields and quality because of its well-structured design.

Smart Control Systems and Monitoring Solutions

Essential Components for Automated Hydroponics

A well-crafted automated hydroponic system (1) depends on sophisticated control mechanisms and monitoring solutions to uphold optimal growth conditions. The essence of automation resides in the integration of sensors, controllers and actuators that function in unison. pH sensors consistently assess the acidity levels of your nutrient solution; however, electrical conductivity (EC) meters monitor the nutrient concentration available to your plants.

Temperature and humidity sensors are vital for sustaining the ideal environment for plant development. These sensors provide real-time data to a central control unit—typically a microcontroller or computer system—which processes the information and initiates suitable actions. Modern systems often include wireless connectivity, allowing you to oversee and modify settings remotely through your smartphone or tablet. Although this technology offers remarkable convenience, it is essential to ensure that the system is properly calibrated to prevent potential issues.

Setting Up Your Control Hub

The control hub functions as the central intelligence of your automated hydroponic system. Initially, you should install a dependable controller unit designed to manage various input and output connections. Many growers favor systems based on Arduino or Raspberry Pi (this is due to their flexibility and cost-effectiveness). You must connect your sensors via waterproof connections; however, it is also essential to ensure accurate calibration for reliable readings. Program your control hub to uphold specific parameters:

• Nutrient solution pH between 5.5 and 6.5

• Temperature range of 65-80°F (18-27°C)

• Relative humidity between 50-70%

• Lighting schedule based on plant type

• Nutrient dosing intervals

Automated Nutrient Management

Implementing automated nutrient management significantly reduces daily maintenance requirements; however, it is crucial to install peristaltic pumps connected to your nutrient reservoirs. This setup allows for precise dosing of individual nutrients. These pumps activate automatically (when EC readings fall below preset thresholds), thus maintaining optimal nutrient levels for your plants.

Moreover, configure your system to perform regular pH adjustments using dedicated dosing pumps for pH up and down solutions. Although this automation ensures that your plants always have access to the right nutrient balance, it also promotes healthy growth and maximum yields. It is essential to include fail-safes in your programming to prevent over-dosing and you should set up alerts for when nutrient levels require manual inspection (because this can help avert potential issues).

Smart Lighting and Climate Control

Your lighting system ought to respond dynamically to environmental conditions (as well as) plant growth stages. It is advisable to install programmable LED grow lights that adjust their intensity and spectrum throughout the day; however, connecting them to your control hub through relay switches or smart controllers enables precise timing and dimming capabilities. Climate control automation requires a coordinated operation of:

• Ventilation fans

• Dehumidifiers

• Heaters

• Cooling systems

• CO2 injection systems

Program these components (to work together) while maintaining ideal growing conditions; however, it’s crucial to optimize energy usage. Set up backup systems and emergency protocols (for protection) of your plants during power outages or equipment malfunctions. Although this may seem straightforward, the intricacies can be quite challenging because each element interacts uniquely.

Remote Monitoring and Data Analysis

Modern automation systems (which are increasingly prevalent) benefit greatly from cloud connectivity and data analytics. For instance, you can install cameras to monitor plant growth and system operation remotely. Set up automated alerts for system parameters that fall outside acceptable ranges; this allows for a quick response to potential issues.

Collecting and analyzing data is crucial to optimize your growing environment: however, it requires a strategic approach to ensure effective implementation. Although challenges may arise, the potential rewards are significant because improved monitoring can lead to better outcomes in production.

• Track nutrient consumption patterns

• Monitor growth rates

• Identify environmental trends

• Document system performance

• Generate maintenance schedules

Utilize this information to optimize your automation parameters and enhance crop yields over time. Regular system analysis is crucial, as it helps identify potential issues before they negatively impact plant health; it also facilitates continuous improvement of your growing strategy.

The cornerstone of effective hydroponic automation resides in establishing redundant systems and adhering to regular maintenance schedules. Although automation diminishes daily hands-on demands, periodic system checks and sensor calibration are indispensable for sustained success. Furthermore, keeping meticulous records of system modifications and maintenance activities is vital (this will build a knowledge base for future enhancements).

Conclusion

Transforming your hydroponic system from a manual operation to an automated one not only conserves your precious time; it also guarantees consistent and optimal growth conditions for your plants. By integrating essential components (such as automatic nutrient dosing systems, pH controllers and environmental monitoring devices), you are effectively positioning yourself for successful yields with minimal hands-on involvement. The incorporation of smart control systems elevates your setup to a new dimension, enabling you to monitor and adjust the growing conditions from virtually anywhere using your smartphone or computer.

However, it is important to remember that, although automation entails an initial investment, the long-term advantages significantly outweigh the costs. You will spend less time on daily maintenance duties, diminish the likelihood of human error and foster more consistent growing conditions that ultimately result in healthier plants and superior harvests. This approach is beneficial for both hobbyists and those managing commercial operations; thus, automating your hydroponic system represents a wise move toward achieving greater efficiency and productivity in your growing endeavors.

As technology (continues) to advance, the possibilities for hydroponic automation will only expand: start with the basics and gradually upgrade your system as needed. Soon enough, you’ll have a sophisticated growing environment that practically runs itself. This allows you to focus on expanding your operation; however, you may also find joy in simply enjoying the fruits of your automated labor. Although there are challenges, the rewards are significant because the future of agriculture is increasingly reliant on such innovations.